Next Generation Pitot Anemometer

The Next Generation Pitot Static Tube Anemometer, Pitot20 (internally named because it first became an operational instrument in 2020), resulted from a multi-year collaboration between the Mount Washington Observatory (MWO), General Electric, and the University of Massachusetts-Lowell Engineering Program. The goals included developing a new operational anemometer for the summit that improved upon the current Pitot19 model and also addressed a few other needs and wants. The first of these was a more simplified design that would allow for easier removal and installation for maintenance and calibration. The second was to explore the possibility of shortening the length of tubes needed to run from the pitot tube itself to the pressure transducers located in the weather room. Lastly, MWO set out to explore an upgraded heating system to reduce the accretion of ice during the worst of conditions on the summit.

View a video about the anemometer design here.

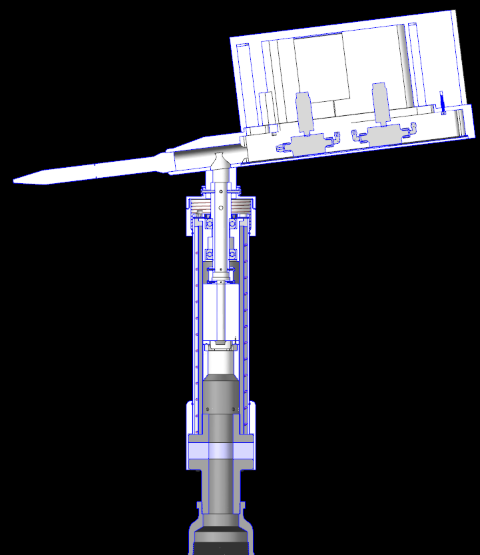

Figure 1. Model of Pitot20

The new Pitot20 system was able to achieve all three of the desired goals. First the new design was not only more robust, but by achieving the second goal the length of tubing needed to be carefully fed down into the tower and delicately hooked up as in Pitot19 was removed, thus drastically improving the installation process. In the new design the pressure transducers were encompassed in the tail of the system. This means that the length of tubes needed to run from the total and static pressure ports to the pressure transducer are approximately six inches in length versus the current tube length for Pitot19 at approximately 70 feet. By reducing the tube length we effectively decreased the internal volume of our system producing a system that is more sensitive to smaller and more rapid wind variations. The new design also allowed us to install a more powerful and effective heating system to help keep Pitot20 deiced in heavier icing conditions.

Figure 2. Pitot20 atop MWO’s instrument tower on a clear day.

The Next Generation Pitot Static Tube Anemometer project began in October of 2015 and testing of the system began on the summit in August of 2018. During this testing period Pitot20 was run side by side with the previous Pitot11 and existing twin Pitot19 to work on bugs in the system and make small adjustments to the mechanical components. Additionally, during Pitot20’s testing phase, it captured a wind gust of 171 MPH, matching the same gust recorded by Pitot19 (see figure 3.).

Figure 3. MWO’s real-time wind tracker captures a 171 MPH gust on both the Pitot19 and 20 anemometers.

In the Fall of 2021, MWO began third-party testing and evaluation of Pitot20 with the University of New Hampshire’s John Olson Advanced Manufacturing Center. Engineers at the Olson Center will provide independent verification of Pitot20 through an analysis of data collected from the instrument during its summit testing phase in addition to evaluating the sensor in a wind tunnel. By using a third-party to evaluate the instrument, MWO aims to add further confidence to the validity of the wind data captured by this instrument and begin the official transition to Pitot202 as one of the “gold” standard sensors at the summit weather station. The completion of this final testing work is expected by early 2022.

The process of designing and building our Next Generation Pitot Static Tube Anemometer is a testament to the continued progress the Mount Washington Observatory makes in improving the methods for data collection. By using new technology we are able to reinvent systems that work in our unique environment while maintaining our legacy of continuously recording the weather on Mount Washington. A very large thank you to all that have worked on this project with the most notable being Dr. Eric Kelsey (Research Professor, Plymouth State University), Keith Garrett (MWO Information Systems Administrator), Pete Gagne (MWO Hardware Systems Specialist), Edward Walton (GE Mechanical Engineer), Michael Gagnon (GE Mechanical Engineer), Matthew Thomas (GE Mechanical Engineer), and Joe Chaves (GE Electrical Engineer, retired 2019).

For more information about MWO Instrumentation contact:

Keith Garrett

Director of Technology

603-356-2137 ext. 230